Low Employee Productivity and the Value of Surveys

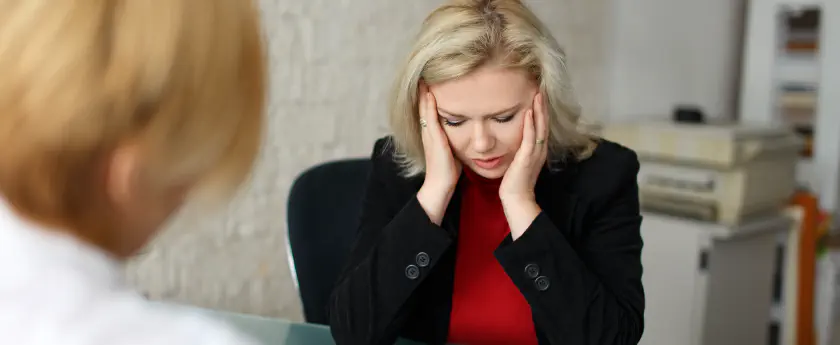

Employees come in late or not at all. When present, their communication is poor and interpersonal relationships ineffective. Those who are present burnout by picking up the work left undone by those absent. Meetings start late and are not managed efficiently. Purchase requests are lost. Questions are asked, but really never answered; a question is asked of three people at three different levels of the organization who give five different answers. Stress mounts. Production or services are not delivered on time. Business declines.

Production, the creation of goods and services, is inadequate to meet customer demand. Employees are ineffective in producing products or in delivering services, fail to bring about the desired and necessary results, and fail to achieve targeted revenues and profits. Low employee productivity is responsible for business decline. Think you have productivity problems in your organization? More than likely, productivity in the organization described here is at rock bottom.

But, why is productivity so low? Can it be improved? Most importantly, how can the desired level of productivity be sustained and nurtured? Before addressing these questions, let us first understand what productivity is.

Productivity is often described as a measure of output per unit of input. It takes inputs to create outputs. That is, it takes how many people at what rate of pay over how much time using what types of resources at what cost to produce a widget that is sold at what price to yield what revenue and profit? Outputs per unit of inputs.

According to the Bureau of Labor Statistics in the US Department of Labor, employee productivity relates output to the labor hours used in the production of that output.

Productivity expectations exist in every industry. Occupational therapists in some practice settings must meet productivity demands of 100%, meaning they must bill for every minute of every hour they are in the facility. Workers in most manufacturing plants are required to meet requisite production numbers each shift. Even restaurants have prescribed numbers of times a table needs to turnover with new guests to offset expenses against revenue.

“In most industries, the yearly increase in the level of productivity that is required to maintain a dominant position in the industry has increased dramatically,” notes Dr. John Sullivan, Professor of Management in the College of Business at San Francisco State University. “The new reality is that productivity increases of between 10 and 25% are now required each year.”

Why do some organizations have employees who are less productive than others? Most researchers agree that there is a higher percentage of unproductive employees in organizations with disorganization, poor information flow, ineffective management; outdated, inadequate or wasted resources, excessive reworking, and process inefficiencies.

Similarly, low employee productivity often exists in organizations that have not aligned their organizational structures with their missions, work flows, and strategic plans. Lack of accountability can also result in low productivity.

In fact, there is a direct correlation between low employee productivity in organizations that also have low employee morale, low employee satisfaction, low employee motivation, and low employee engagement.

Realizing the significant impact that employee perceptions and attitudes have on work performance and organizational results, many organizations use survey research to help identify the root causes of and solutions to low productivity.

A group of researchers conducting a root cause analysis looks at the situation after it has occurred and identifies problems and issues before generating solutions. In this way, the real or basic ‘root’ cause of the problem is identified and resolved by looking at a multitude of factors, including processes, systems, resources, and people.

Questionnaires are often used to gauge levels of employee satisfaction and engagement as a predictor of employee productivity. Employees indicate the degree to which a statement reflects their situation in the workplace. Such items might include the following:

- I understand what is expected of me in my job.

- I am satisfied working for this organization.

- I receive the training I need to do my job.

- I feel like I am part of a team in this organization.

- My workload is commensurate with my responsibilities and authority.

- I have the resources necessary to do my job.

- I would recommend that a friend work here.

Questionnaires are used to capture employee thoughts on morale and motivation on the job, both predictors of productivity. Interviews can be used to clarify responses from the questionnaires or to probe for additional information. Focus groups can be conducted to gather additional points of view or used as collaborative problem solving groups on productivity issues.

And, such questionnaires may be used as retention studies, exit interviews, and ongoing gauges of employee perceptions related to loyalty, satisfaction, morale, engagement, and productivity, administered on a regular basis.

Organizations that care enough to gather employee feedback through survey research methods must care enough to study the results and do something about them. If not willing to spend time and resources to meet identified needs, the organization might just as well not have bothered asking for feedback in the first place. Research shows that employees will support action plans, even if those plans differ from their preference, if they have some input into the process.

While part of that employee input should be focused on identifying barriers to productivity, an equal part of that input should be focused on generating solutions, sharing ideas for increasing employee satisfaction, morale, and engagement to heighten productivity at work.

A recent study found the average construction worker operated at about 40% efficiency. Professor Roger Liska, Chair of the Department of Construction Science and Management at Clemson University in South Carolina, found that the low productivity was actually due to management problems, rather than individual construction workers.

“More than half of that lost productivity could be traced to delays waiting for equipment and supplies, inefficient company processes, and work rules and congested work areas,” noted Liska. “These are things where better management can really have an impact.”

The responsibility for improving productivity in organizations can rest in many areas, including human resources, the functional department itself, or an outsourced firm. Regardless of who facilitates the process, the focus should be on factors that support individual and team performance.

The New Zealand Ministry of Business, Innovation and Employment identified seven drivers of workplace productivity in its Workplace Productivity Agenda. The drivers include building leadership and management capabilities, creating a productive workplace culture, encouraging innovation and use of technology, investing in people and skills, providing a structure and process with which to organize work, promoting networking and collaboration, and measuring what matters.

It’s important to have a clear vision about business goals and objectives. It’s equally as important to have leaders who inspire people to work collaboratively towards those goals. A positive work environment motivates people and conveys value related to employee insights and contributions.

An organization’s impactful use of technology and use of innovative strategies improves productivity and becomes a competitive advantage. Similarly, collaborations in the form of partnerships, joint ventures, and supplier relationships often reduce the cost of doing business and provide access to stimulating new ideas, all of which enhance productivity.

Employees who receive on the job education and training in knowledge and skills generally require less supervision, work well independently, and are effective communicators. They are highly productive workers. How can an organization not invest time and money to support the work of promising employees?

”The drivers emphasize the need to align everyone in the workplace towards better performance and are about working smarter not harder,” says David Smol Chief Executive of the Ministry of Business, Innovation and Employment. “It is really important to assess the value of any investment you make in improving your workplace productivity. This helps you understand the things that make the biggest difference. For example, is it the size of your organization’s structure, the skill levels of your staff, the size of your market, or some other factor?”

Dr. John Sullivan has identified 22 factors that influence individual and team productivity across organizations. Among these factors are effective managers and leaders who set direction, coach, mentor, and motivate; prioritization of tasks and processes for ‘impactful resource allocation’; sharing of best practices and ideas; formal recognition of employee contributions; effective and timely communication and feedback to reduce errors and frustration; and integration of business resources, processes, and systems.

In his article, Increasing Employee Productivity: The Strategic Role that HR Essentially Ignores, Dr. John Sullivan emphasizes that performance metrics provide focus, feedback, and result in continuous improvement.

In her article, Setting Goals to Measure and Monitor Productivity in the Workplace, Roslyn Frenz advocates involving employees and supervisors in discussions about what productivity improvements need to be made, including materials selection, excessive waste, and labor cost.

Once those decisions have been made, variables are identified to use in goal setting (e.g., number of employees per task, work hours). The productivity goal is identified for each variable; the difference between the current and the desired variable is calculated. Those variables with the largest discrepancies are selected for monitoring; a timeline is developed to track productivity goals (e.g., daily, weekly, monthly, quarterly).

Concurrently, the productivity team analyzes tasks related to the variables under study and identifies strategies on increasing productivity. This might include identifying a less expensive supplier of same quality materials and streamlining a job task to take fewer people or less time. Of course, it is important to actually test the new ideas to determine whether they improve productivity before making final recommendations!

When Henry Ford incorporated the Ford Motor Company in 1903, his goal was to make a motor car for the masses. Yet, workers at the Ford factory in Detroit made just a few cars each day. Henry Ford realized that a more efficient production process was needed to meet customer demand. He needed to improve productivity at the Ford Motor Company.

Over several years, Henry Ford invested in hiring the right people for the right job. He offered education and training. He created innovative machines and processes to use for different steps in the manufacturing process. In fact, Ford re-organized the entire production process. He even raised worker pay to $5.00 a day, a rate unheard of in 1914.

Ford believed that productivity would increase by keeping employees satisfied on the job through re-engineering systems and processes, providing education and training, incentives, and ensuring employee satisfaction. Ford was right.

Low productivity in the workplace can decimate a business. To learn how NBRI can help you identify root causes of low productivity and generate solutions to boost productivity, contact us at 800-756-6168.

Terrie Nolinske, Ph.D.

Research Associate

National Business Research Institute

By submitting this form you agree to our

By submitting this form you agree to our